As one can see that

the transportation of goods from rails is much more convenient that roads or

airways because large amount of goods can be transported at a time with much

cheaper rate and low fuel consumption making it affordable and environment

friendly (less pollution). But, due to its late and slow service, no one risk

to prefer it. The goods which should be delivered within 3 days takes more than

10 days to get delivered increasing both the percentage cost of transportation

and loss of the owner. Also, the Railways doesn’t deliver proper goods to

owner; there are some problems related to quantity and quality of good always.

Taking these circumstances, one always thinks what are major developments

happening in Indian Railways related to these freight trains?? The post will

cover the latest technical developments of Indian Railways which include the

strategies for improving the condition of freight trains!!

Before start, why

these goods train are so slow? One never thinks on it because even our

passenger’s train gets delayed. The biggest reason becomes the overcrowded rail

routes in which preference are more to passenger’s train than freight train

which operates in large quantities; making hardly any route free to move. The

second reason becomes the large loads of these goods trains and the old

outdated tracks which doesn’t permit to go beyond 50km/hr. The final reasons

are the locomotives having very less tractive effort and low hauling capacity

to pull the fully loaded fifty wagons (bogies) train.

To compensate this,

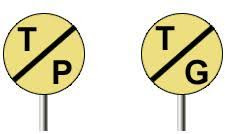

the first major and mega development are the DEDICATED FREIGHT CORRIDORS (DFC)

covering the four quadrilaterals and major cities of India. These will become

the core of goods train allowing the trains to run with almost 110 wagons at a

speed of 100km/hr max. Important part being that only freight trains are

allowed to move on these routes preventing the delay and delivering the proper

goods on time. The system is equipped with high tech machines increasing the

speed and accuracy of the work with much better materials. To ensure more

safety and quality of goods, various storage units and packing machines are

installed to these routes. For more info, visit to my post: DEDICATED FREIGHT

CORRIDOR (THE RAILWAYS GAME-CHANGER).

|

| dedicated freight corridor |

The one incidence that

should be discussed before continuing that one goods train of Indian Railway is

1354 days late (almost 4 years). The incident is bit shocking; taking place

when one owner ordered the transportation of 21 fertilizers wagons from Visakhapatnam

to Basti on 14 November, 2014. He got only 20 wagons of fertilizers and one

wagon was missing. When he complained, Railways said that the wagon was bit

heavy to transported and will be transported later. But then the last wagon was

delivered after 1354 days. When owner asked for compensation, railways said that

it was his fault that he had not correctly matched its products. Thus, the big

evolution is necessary to remove such big mistakes in Railways.

Now, the biggest development that should be

undertaken are the better hauling locomotives that are enough pull the high

weight wagons. We observe that old ALCO locomotives are still used for hauling

the heavy wagons like WDM3A, WDG3A etc. These locomotives still have low hauling

capacity and high fuel consumption with major pollutions. But still these

locomotives are most successful locomotives for Indian Railways.

Taking in account the

current operational locomotive, we have the latest EMD locomotives with high

traction power like WDG4, WDG5 and WDG4D. The high-powered diesel operated

engines can easily move the trains with decent speed. Besides, the diesel

locomotives give more traction power as compared to electric locomotives, thus

are necessary.

Next, in electric

variations we have WAG5 basically used in twin coupled and WAG7 locomotive. These

two locomotives are highly used in rail tracks. But when it comes to monster,

we have WAG9. This locomotive is the most powerful locomotive of Indian Railways

having 6350HP. This locomotive can easily haul the 60-70 good wagons with great

speed. This green coloured locomotive is most commonly used in Freight tracks and

on busiest routes.

|

| WDG4 |

|

| WAG7 |

These are some current

operational locomotives being used for long time. But what about the ultra-power

locomotives or these are only number?!

The first major positioner

is WDG4G, a locomotive imported from general electric, Germany. This diesel

variant locomotive becomes the most efficient and powerful diesel locomotives

for goods trains having decent hauling capacity and fuel efficient. The locomotive

would be manufactured in the factory of MARHOWRAH, BIHAR.

|

| WDG4G |

Next to talk about the

biggest accomplishment of ‘MAKE IN INDIA’ or Indian Railways project; a new

conversion locomotive named WAGC3. This locomotive was manufactured with use of

two locomotives, WDM3A and WAM4. The world’s first diesel to electric

conversion locomotive would again be used in hauling freight trains in

Dedicated Freight Corridor. For more info visit to post: WDG-4G.

|

| WAGC3 |

Finally, the BEAST of

Indian Railways; the mega hauler locomotive, WAG12. This locomotive is most

powerful locomotive of India, having 12000HP. This locomotive was imported from

ALSTOM, FRANCE which remarks a big history in Indian Railways. This locomotive

can easily haul 100-120 wagons at a top speed of 110km/hr. The locomotive is

also equipped with high modern equipment’s and used in twin sectioned for extra

power. This locomotive would be proved to be a big gamechanger in Railways. For more info visit to my post: WAG12.

|

| WAG12 |

Lastly, the coming

soon locomotive; again, a mega conversion after WAGC3 named WAG11 locomotive.

This locomotive would be fusion of WDG4 and WAP7 locomotive. This locomotive was

also counted among powerful locomotives for freight trains.

Thus, these developments

in goods train will surely bring a mega change of transportation where more

preference becomes the rail transport and decreasing the transportation rate to

great extent making it cheaper than others. Soon, the country will be counted

among the powerful nation in rail transport and services and people can see the

better conditions for the rail transport.

HOPE, YOU WOULD LIKE

THE INFORMATIONS AND CONTENT.

REFERENCES:

CONTENT: MY IDEAS AND

THOUGHTS

IMAGES: GOOGLE IMAGES